For decades, moldboard plows, disks and field cultivators, all horizontal tillage tools, have been the go-tos for fieldwork. That’s changing as fears about climate change come into focus.

Sooner or later, you’re going to be pushed (or led, depending on your perspective) toward vertical systems by government incentives.

“The world is asking farmers to fight climate change by reducing tillage and planting cover crops,” says Ken Ferrie, Farm Journal field agronomist.

“Governments want you to adopt vertical systems to disturb the ground as little as possible and keep it covered year-round — essentially what existed when our cropland was covered by native prairie. I expect climate-smart initiatives will include financial incentives for reduced tillage and cover crops. That will create opportunities for farmers in vertical systems. However, soil layers left by horizontal, full-width tillage systems could cause those vertical systems to fail.”

No one argues horizontal farming doesn’t have advantages.

“Vertical farming tools are like golf clubs,” says Ken Ferrie, Farm Journal field agronomist. “Each has its own purpose. You use some every season and others only when needed. In golf or farming, having the right tools and knowing how to use them is crucial to success. That includes planter setup, weed management and tillage tools. While treating all fields the same makes farming simple, it’s like going golfing with only a driver and a putter — it won’t get you the best score.”

“Horizontal spring tillage lets us plant into warmer soil with more uniform moisture,” Ferrie says.

“That gets plants off to a faster start. Weed control is cheaper, and fewer specialized attachments are required on planters. But unfortunately, horizontal tillage doesn’t match up with the climate incentives I see coming down the pike.”

Vertical farming can be profitable, but it’s harder to manage.

“Among our consulting clients, vertical systems — no-till, strip-till and others — produce the highest return on investment,” Ferrie says. “On the other hand, they also produce the lowest. It depends on whether growers understand and know how to manage their vertical systems.”

This story is the first in a series of articles that will explain how to transition to vertical farming. Let’s set the stage:

What is vertical farming?

“Merely no-tilling or using a vertical harrow or similar vertical tool does not mean you’re in a vertical system,” Ferrie says. “A vertical system exists only after all horizontal layers, usually caused by horizontal tillage, are removed, and the soil is managed so as to not put them back in.

“A vertical system lets roots grow downward without restriction,” he adds. “The soil’s bulk density changes gradually, versus suddenly, so roots can adjust and penetrate, rather than flattening out along the top of a layer. Likewise, without sudden density changes, water will move downward and be stored in pore spaces. It will wick back up as water evaporates from the surface of the soil or through plant leaves.”

Horizontal versus vertical

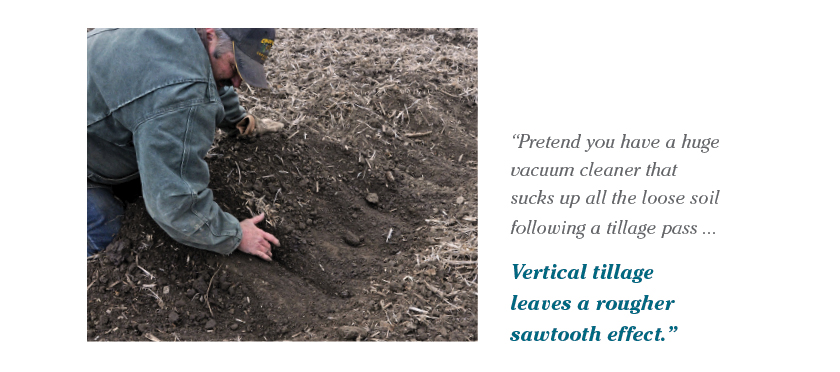

“Pretend you have a huge vacuum that sucks up all the loose soil following a tillage pass,” Ferrie says. “After horizontal tillage, you would find a flat horizontal plane. Vertical tillage leaves a rougher sawtooth effect.”

TOOLS FOR VERTICAL FARMING

Vertical tools include disk rippers, in-line rippers, chisel plows, field cultivators with spikes instead of sweeps, strip-till bars, row warmers, vertical harrows and no-till planters.

“Most farmers mix and match tools for primary and secondary tillage,” Ferrie says. “In horizontal systems, they might use a vertical tillage tool, such as a disk-ripper, in the fall for primary tillage and follow with a disk or field cultivator when spring rolls around. Or they might make one pass in the spring on soybean stubble with a soil finisher or high-speed disk. But all these secondary tools leave a horizontal tillage layer, a sudden density change that roots might have trouble coping with.”

For vertical farmers, typical programs include:

- Chisel plowing in the fall and one or two passes of a vertical harrow in the spring.

- Vertical harrowing in the fall, leaving a sterile seedbed for planting in the spring.

- Vertical harrowing in the fall, followed by one pass with a vertical harrow in the spring to warm and dry soil for planting.

Conventional vertical tillage is fall primary tillage with a chisel, disk-ripper or in-line ripper (shattering soil across the width of the implement) and leveling in the spring using a vertical tool with no gang angle. “The leveling pass is like screeding concrete — knocking peaks off into the valleys, rather than using a sweep to level soil from below,” Ferrie says.

No-till or strip-till after all the old soil layers have been removed.

Most farmers need to implement multiple practices.

“In some fields, no-till might work great on 70% of the acres, but the other 30%, with drainage or soil-type issues, need to be strip-tilled,” Ferrie says. “So the whole field will work better in a strip-till format. Sometimes a more aggressive fall program is required to manage continuous corn residue, wheel track issues, manure application or new fields that need compaction removed or fertilizer mixed in.”

GOLDEN RULES OF VERTICAL SYSTEMS

When consulting clients consider transitioning from a horizontal to a vertical farming system. Farm Journal Field Agronomist Ken Ferrie offers four rules he considers essential:

- The shallower a horizontal soil density layer, the more it costs in terms of yield and profit. “A 2″-deep layer causes more problems than an 8″ plow sole,” Ferrie says.

- The last tillage pass before transitioning to a vertical system must not be horizontal (because it will leave a density layer that will last for years).

- Keep the seedbed sacred. “Ear count is always of utmost importance,” Ferrie says. “That requires a perfect seedbed, and creating one takes more management in vertical systems. If you’re not ready to put forth the time and management to achieve a uniform stand in a vertical system, it’s better to remain in a horizontal system.”

- Allow three years to transition to a vertical system. “It will take that long to acquire management skills and equipment and prepare your soil for a vertical system,” Ferrie says.

Source : AG Web

“Vertical farming tools are like golf clubs,” says Ken Ferrie, Farm Journal field agronomist. “Each has its own purpose. You use some every season and others only when needed. In golf or farming, having the right tools and knowing how to use them is crucial to success. That includes planter setup, weed management and tillage tools. While treating all fields the same makes farming simple, it’s like going golfing with only a driver and a putter — it won’t get you the best score.”

“Vertical farming tools are like golf clubs,” says Ken Ferrie, Farm Journal field agronomist. “Each has its own purpose. You use some every season and others only when needed. In golf or farming, having the right tools and knowing how to use them is crucial to success. That includes planter setup, weed management and tillage tools. While treating all fields the same makes farming simple, it’s like going golfing with only a driver and a putter — it won’t get you the best score.”